Description

Principle Oil or Gas combustion hot air furnace, the fuel is burnt at firebox and the high temperature is produced. The quantity of heat will conduct to air to be heated through heat exchange device. Through heat exchange, the temperature of air is dropped to less than 250o C and the air will be discharged. The air to be heated is sent to hot air furnace through distribution blow fan. After absorbed heat to the rated value, the air will be sent from the vent of hot air. When the temperature of hot air reaches the rated upper limit,the burner can stop or turn to small fire automatically.When the temperature of hot air drops to the rated low limit, the burner can burn or turn to big fire automatically.

Application:

1. Industries for using the furnace For example.

2. Metal surface covering or coating high temperature solidification after plastic spray or paint spray.

3. Medicine drying the herbal medicine material of traditional Chinese medicine.

4. Grain processing drying the grain and starch.

5. Food cake baking, convenient noodle, fine dried noodle drying, transmission belt, spec baking machine.

6. Wood processing wood drying, fibre plate and compound plate drying.

7. Textile, Printing and dyeing printing drying, heat shaping, hot air widening.

8. Chemical products drying the chemical raw material.

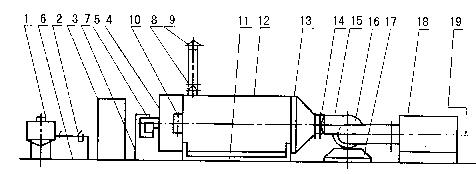

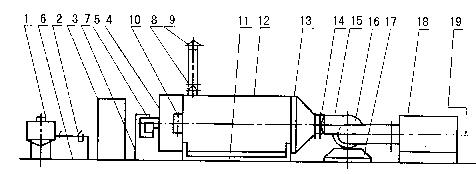

Drawing of hot air boiler:

| 1.Oil storage tank | 2.Total valve filter | 3.Control box | 4.Burner Base Base | 5.Burner Block | 6.Tubing | 7.Into the pipeline |

| 8.Rain-hat | 9.Chimney | 10.Hot air exports | 11.Base | 12.Heat exchanger | 13.Air inlet | 14.over |

| 15.over | 16.Blowers | 17.Shock absorption seats | 18.Air filter | 19.Air to enter |

|

|

Item Model Unit

Item Model Unit